Facebook Twitter LinkedIn Youtube

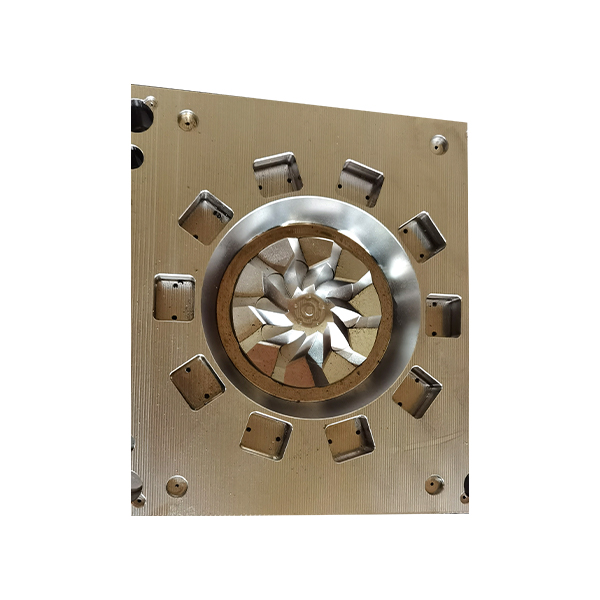

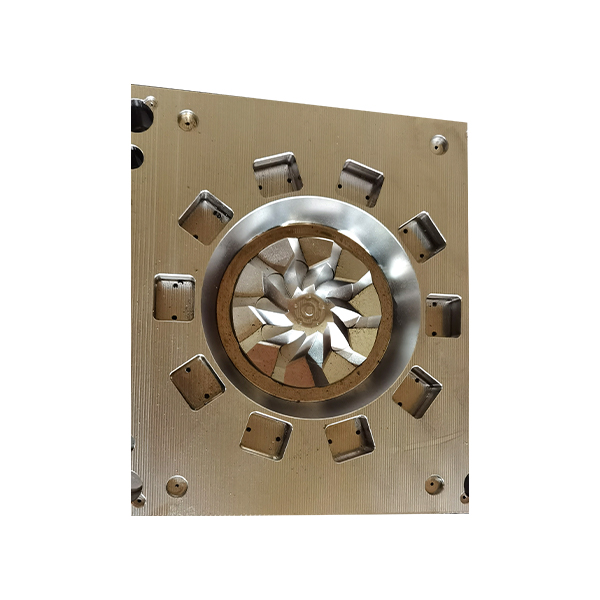

High Quality Industrial Moulds Wholesaler Industrial moulds play an essential role in manufacturing processes across various industries, including the automotive, electronics, and medical sectors. Th...

High Quality Washing Mould Manufacturing Washing mould is an essential process in many industries, particularly in manufacturing and production. Over time, moulds can accumulate residues, debris, and...

Wholesale car interior mold in China The automotive industry has experienced tremendous technological shifts in recent years, particularly in the realm of car interior mold design. Traditionally, cre...

Sale auto lamp mould Supplier The auto lamp mould plays a pivotal role in the automotive industry, allowing the production of various types of automotive lighting components, including headlights, ta...

OEM/ODM plastic crate mold producer When it comes to producing durable and efficient plastic crates, one of the crucial factors that impact the overall performance is the choice of material for the p...

Design automotive mould Factory The production of automotive moulds is a critical aspect of the automotive industry, requiring meticulous attention to detail and a rigorous quality control process to...