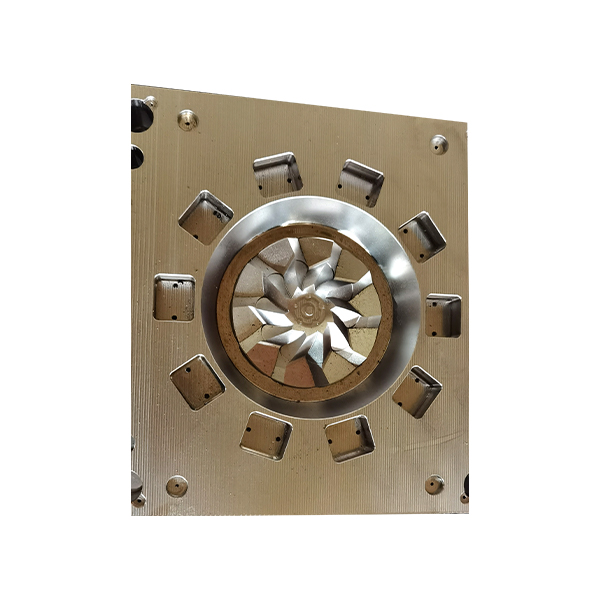

ABS Fan Blade Mould

The surface finish of the precise fan blade mould is very high, and the overall balance is also very high. High-gloss injection moulding technology is usually adopted to produce ABS fan blade moulds. High-gloss injection moulding is also known as rapid thermal cycle injection moulding technology.

1. Kelong's fan blade mould surface has no melting marks, and the surface highlights achieve a mirror effect

2. Improve the strength and surface hardness of plastic parts;

3. Make thin-wall moulding improve injection fluidity, improve product quality and strength;

4. The injection cycle of thick-walled moulding can be reduced by more than 60%;

The high-gloss injection moulding process also has very high requirements on the fan blade mould.

① The inner surface of the mould requires a very high finish to ensure the surface quality of the product;

② The opening of pipes inside the mould must be reasonable to ensure rapid heating and cooling;

③ The pipes inside the mould should have good thermal conductivity;

④ Due to the continuous heating and cooling in the production process, the steel used for the mould is better;

⑤ In the process of using, pay special attention to the maintenance of the mould to ensure that it is dry and dust-free.

English

English Español

Español

.jpg?imageView2/2/format/jp2)

.jpg?imageView2/2/format/jp2)